Quid Aramid-ipsum mixta fabricae ?

Aramid-ipsum mixta fabricae est summus perficientur compositum materia combining Aramid fibris (notum est lenta) cum ipsum fibris (clarus enim rigorem). Hoc Hybrid structuram liberat exceptis viribus-ut-pondus componat, faciens idealis ad aerospace, automotive et ballistic applications. Dissimilis pura ipsum fibra, in Aramid pars addit impulsum resistentia, cum carbonis fibris compensare Aramid scriptor inferioribus compressive viribus.

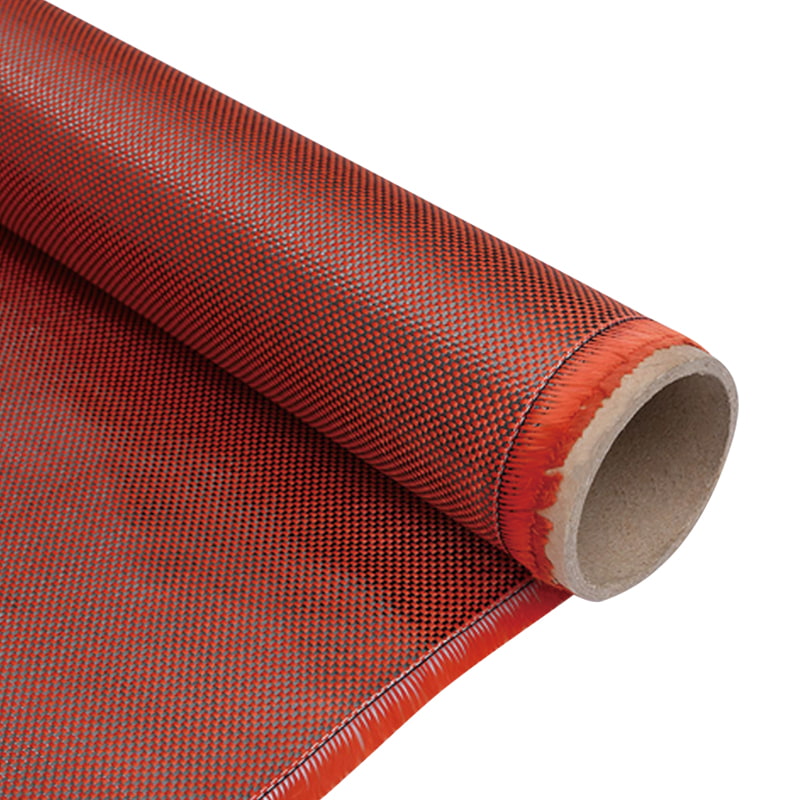

3K 1000D / 1500d patet / PWILL Aramid Carbon Mixed Carbon Fiber Textus fabricae

Key components de hybrid fabricae

- Aramid fibris : Calor-repugnans organicum polymers cum altum tensile vires

- Carbon fibris : Lightweight Crystalline Carbon Structures superior rigor

- Polymer matrix : Typically epoxy vel thermoplastic resins binding fibris

Aramid-ipsum mixta fabricae nobis Kevlar : A detailed collatio

Cum aestimandis Aramid-ipsum mixta fabricae nobis Kevlar Plures perficientur differentias emerge. Dum Kevlar (a genus Aramid) excellit per Conscidisti resistentia, in Hybrid fabricae offert meliorem dimensional stabilitatem et compressive viribus.

Mechanica proprietatibus collatio

| Res | Aramid-ipsum misce | Pura Kevlar |

|---|---|---|

| Tensile vires | 3,500-4,500 MPA | 3,000-3,600 MPA |

| Compressive fortitudinem | 1,200-1,800 MPA | 500-700 MPA |

| Impact resistentia | Praeclarus | Praestans |

| Pondus | 1.45-1.55 G / CM³ | 1.44 G / CM³ |

Applicationem-specifica commoda

- Et Hybrid fabricae maintains figura melius sub compressionem quam pura Aramid

- Carbon fibris reducere subrepit deformatio comparari omnibus Aramid solutions

- Kevlar manet superior pro pura ballistic applications debitum ad fibra elasticitas

Optimus resinae ad Aramid-ipsum hybrid compositorum : Electio criteria

Eligens Optimus resinae ad Aramid-ipsum hybrid compositorum Exigit balling adhaesionem, dispensando characteristics et finis-usus perficientur. Resina ratio debet accommodare differentia alimentorum fibra superficie vires cum resistente microcracking.

Resina perficientur matricem

| Resin type | Processus temp | Fibra adhaesionem | Impact perficientur |

|---|---|---|---|

| Epoxy | 120-180 ° C | Praeclarus | Bonum |

| Phenolic | 150-200 ° C | Bonum | Aequus |

| POLYIMIDE | 250-350 ° C | Praeclarus | Praeclarus |

Critica Electio factors

- CTE (coefficientium scelerisque expansion) matching inter fibris et resinae

- Humorem effusio characteres ad velit applications

- Remedium DECREMENTUM parametri Afensing dimensional stabilitatem

Aramid-ipsum fabricae Savings PECULIUM Analysis : Engineering beneficia

In Aramid-ipsum fabricae pondus savings analysis Reveals quid hoc materia dominatur pondus-discrimine applications. Comparari Aluminium Alloys, in Hybrid fabricae praebet equivalent rigorem LX% pondus reductionem.

Pondus comparationis per materiae

| Materia | Density (G / CM³) | Rigorem equivalent pondere |

|---|---|---|

| Aramid-ipsum misce | 1.5 | 1.0 (Baseline) |

| Aluminium (VI) LXI | 2.7 | 1.8 |

| Ferro A36 | 7.85 | 5.2 |

Design Optimizization occasiones

- Reducitur inertia onerat in motu components

- Inferius Support Structure Requirements Ob Minor

- Improved Energy efficientiam in Lorem Applications

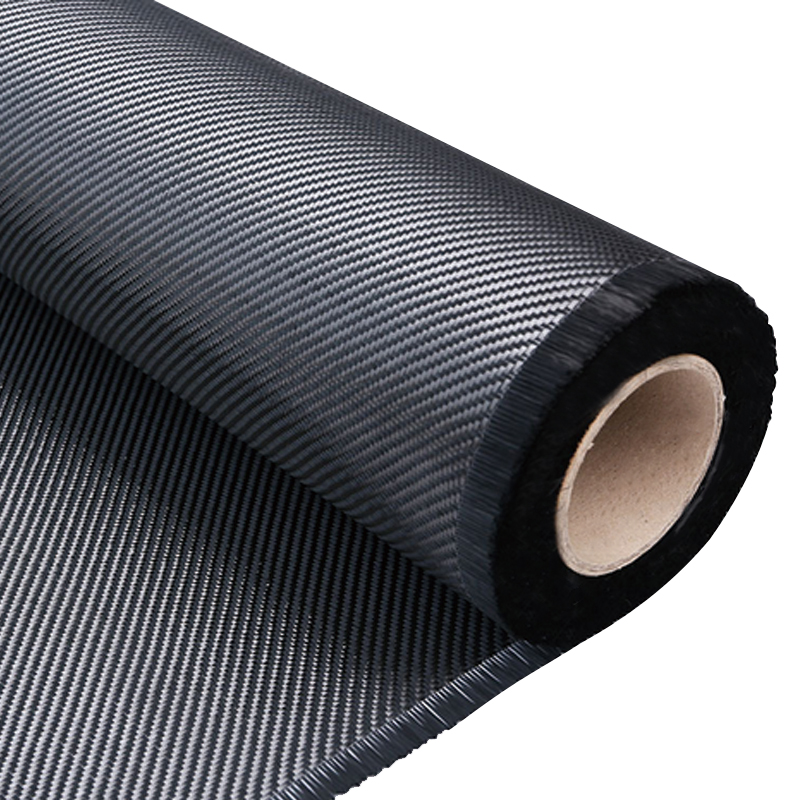

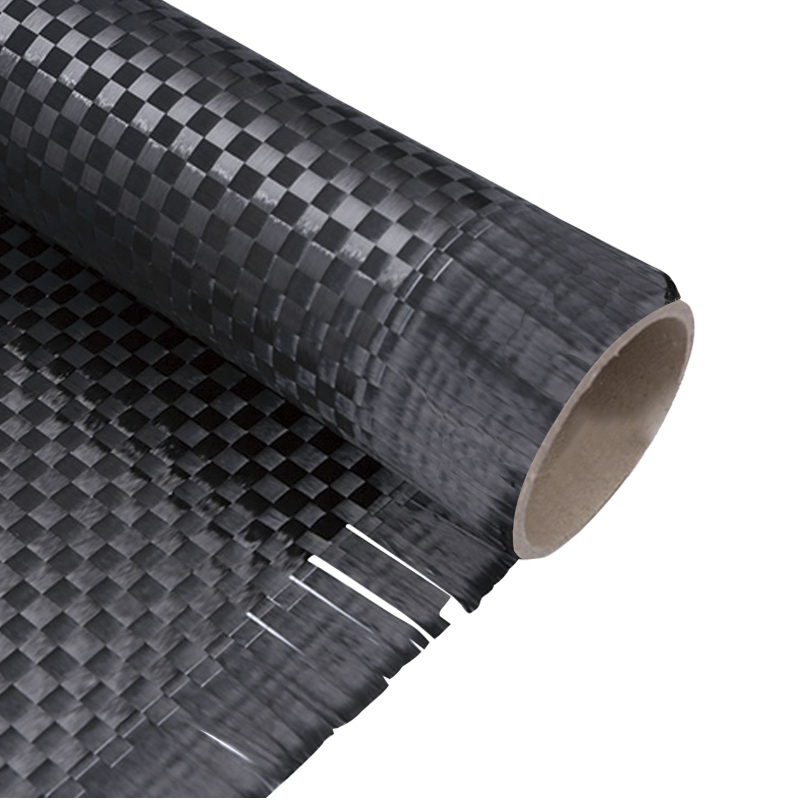

Aramid-Carboni texentes patterns ad impulsum resistentia : Design considerations

Optimizing Aramid-Carboni texentes patterns ad impulsum resistentia Exigit intellectus quomodo fibra orientation afficit industria effusio. Hybrid textilia saepe uti mutatio Twill et Satin texit ad statera drapeability et impulsum perficientur.

Texentes exemplum perficientur collatio

| Type texere | Impact Energy effusio | Drapeability | Lassitudine resistentia |

|---|---|---|---|

| Patet texentes | Bonum | Aequus | Praeclarus |

| 2x2 twill | PERPLICENTER | Bonum | Bonum |

| 4HS Satin | Praeclarus | Praeclarus | Aequus |

Layer Stacking Strategies

- Alternants 0 ° / XC ° et ± XLV ° layers multi-axis impulsum praesidium

- Gradual transitus zonas inter dissimilar materiae ne delamination

- Hybrid suturis artes ponere fibra alignment per deformatio

Aramid-Carbon Hybrid fabricae temperatus terminum : Thermal stabilitatem

Intellegentia Aramid-Carbon Hybrid fabricae temperatus terminum est crucial ad summus temperatus applications. Dum carbonis fibris sustinere extrema calore, Aramid pars typically fines altiore perficientur ad 300-350 ° C continua nuditate.

Thermal perficientur characteres

| Materia | Continua usus temp | Apicem brevi-term Tempus | Scelerisque conductivity |

|---|---|---|---|

| Aramid-Carbon | CCC ° C | CDL ° C | 5-10 w / MK |

| Omnes, ipsum | D ° C | M ° C | 50-150 w / MK |

| Aramid | CC ° C | CD ° C | 0.04 w / MK |

Scelerisque administratione ars

- Protective Ceramic coatings extensa summus temperatus ministerium

- Hybrid layups cum Graded scelerisque tutela layers

- Active Refrigerant Integration In Extreme environments