The** ipsum aramid fabricae ** represents a synergistic approach to composite engineering, blending the high specific stiffness of carbon fiber with the outstanding energy absorption capacity of aramid fiber. For critical applications—ranging from aerospace fairings to racing shells—determining the precise mixing ratio of these two fibers is a highly technical undertaking. The goal is to maximize the composite's overall mechanical profile by strategically trading off super-high stiffness for improved resistance to catastrophic failure.

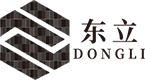

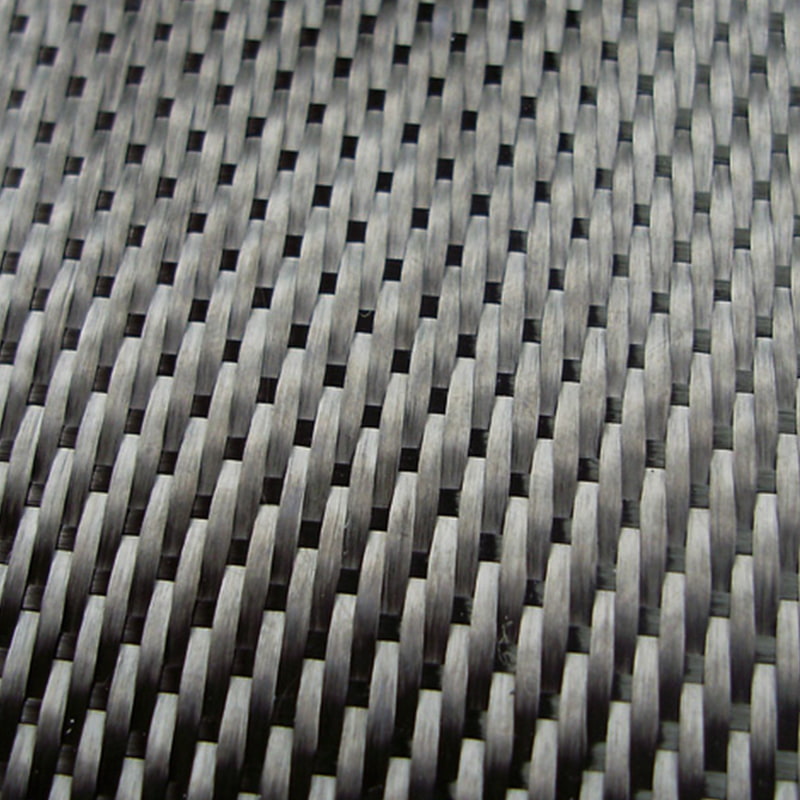

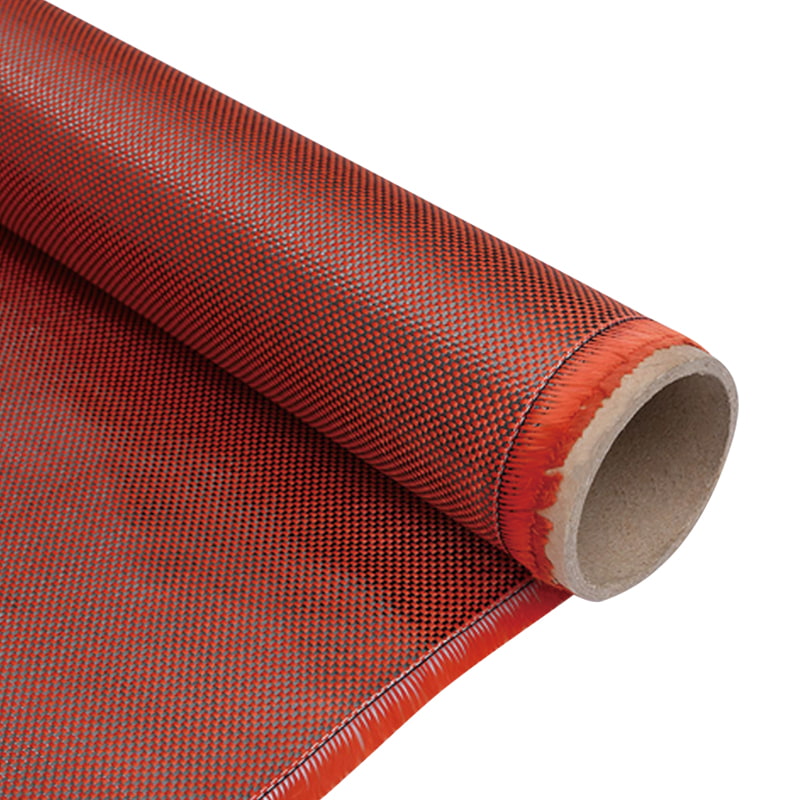

Red/Nigrum Aramid Carbon Mixtum Carbon Fiber Texta Fabric

Definiens Librans Actus: Modulus vs. Toughness

Machinarii computare debent fractionem fibrarum praecisarum voluminis ad obtinendam stateram desideratam inter duas proprietates mechanicas primarias.

Colligendis Optimal carbonis ad rationem aramidis pro compositis hybrid

- ** Carbonis munus: ** Carbonis fibra maiorem vim distrahendi et modulum praebet. Contentum carbo superiori ad leviores, rigidiores structuras ducit, sed cum tolerantia damnum imminutum.

- ** Munus Aramid: ** Aramid (Kevlar vel Twaron) defectus limitis est. Altitudo eius elongationis et excellentis vibrationis facultatem madefaciendi absorbet et impulsum energiam dissipabit, rima propagationis efficaciter comprehendens. ad determinandum Optimal carbonis ad rationem aramidis pro compositis hybrid omnino pendet in applicatione requiritur salus factoris contra locales impetus.

Modulus librans et impactus resistentiae in fabricae carbonii aramidis Designs

Necessitudo reciproca inter rigorem et duritiam in compositis hybridis est. Purae structurae carbonii modulum altum praebent, sed resistentiam ictum pauperem; purus aramid optimum impulsum praebet resistentiam sed modulum humilem. Prosperum consilium involvit Modulus librans et impactus resistentiae in fabricae carbonii aramidis by adding enough aramid content (typically 25% to 50% by volume) to enhance post-impact residual strength without overly compromising the overall stiffness required for structural integrity.

Hybrid ratio effectus in Key Mechanica Properties Tabula

| Carbon:Aramid Ratio (Approx. Volume %) | Modulus tensile (Suffness) | Impulsum Toughness / damnum TOLERATIO |

|---|---|---|

| 75:25 (Carbon Rich); | Summus | Moderatus (pronus ad fragilis defectus) |

| 50:50 (Libra) | Medium-High | Summus (Excellent for localized impact protection) |

Impulsum mollitiam: Analyzing Aramid Conlationem

Verus valor componentis Aramidorum per strictorem ictum tentationis quantitatus est.

Impact spissitudo analysis of carbonis aramidis hybrid fabricae

- **Energy Absorption:** Aramid fibers primarily contribute to the material's impact performance by exhibiting large amounts of inelastic deformation (fibrillation) before complete rupture. Haec mechanismus defectus valde localatus magnam quantitatem motuum energiae destruit, quae in ecclesia confirmata est Impact spissitudo analysis of carbonis aramidis hybrid fabricae per Charpy vel Izod probat.

- **Defectum Modus:** In compositis carbonibus puris, impulsus saepe in fractura acuto pullout fibra resultat. In **ipsum aramid fabricae**, the aramid fibers bridge the crack, preventing catastrophic delamination and allowing the composite to retain a higher percentage of its original strength after impact damage.

Munus Interfacialis Shear Fortitudo et Defectum Mechanismi

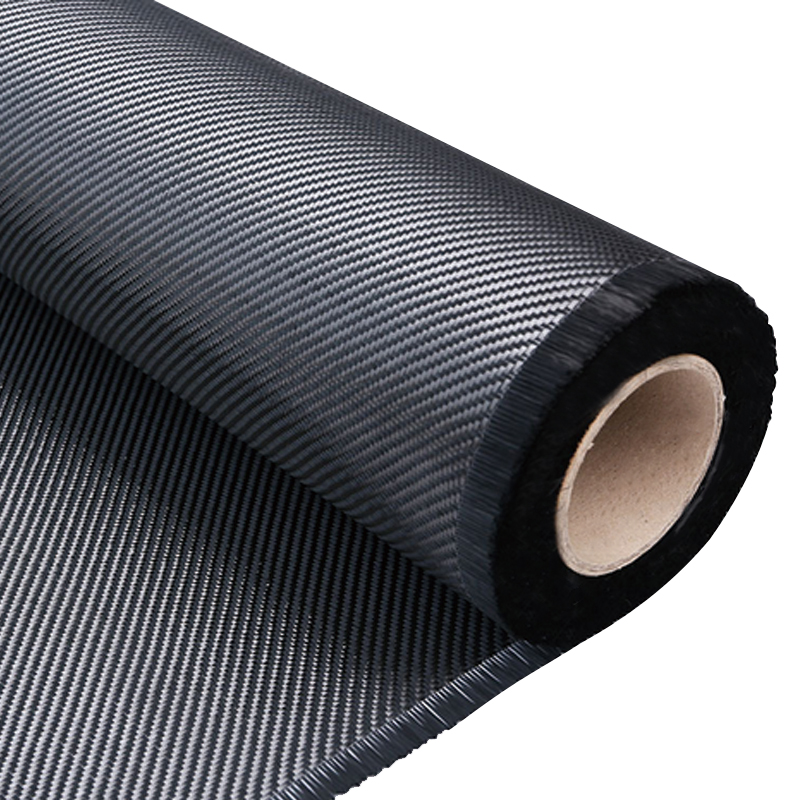

Meditatio inter fibra et matrix resinae critica est. Altitudo interfacialis tondendi viribus opus est ad curandum ut accentus efficienter inter carbonem, aramidem et resinam transferatur, ne praematuri vinculi defectus, qui alias capacitatem materiae totalis ictum absorptionis labefactat.

Structural integritas: Shear et Delaminatio Repugnantia

Vltra vires planae resistentia laminatis ad vires ex-planas est praecipua firmitatis.

perpensis Vires interlaminares tondendas laminas carbonis aramidis fabricae

- **ILSS:** Interlaminaris Shear Fortitudo (ILSS) clavis est metrica ad dijudicandam compagem qualitatis inter stratas. Minimum ILSS indicat matrix infirma vel pauper fibra udus, ducens ad immaturam delationem. Cum perpendendis Vires interlaminares tondendas laminas carbonis aramidis fabricae , the difference in surface chemistry between carbon and aramid fibers must be compensated for during the prepreg manufacturing process to ensure strong matrix adhesion across all fiber types.

Focus application: Designans fabricae carbonii aramidis ad partes automotivas summus perficientur

In sectore autocineto, carbonis aramidalis fabricae magis magisque in componentibus utuntur sicut bulkheads, structurae fragor, et tubi gb. Designans fabricae carbonii aramidis ad partes automotivas summus perficientur specie petant damna tolerantiae. The aramid layer is often positioned on the outer surface to absorb road debris impact, protecting the underlying, high-modulus carbon layers essential for stiffness.

Jiangyin Dongli Nova Materia: Excellentia in Compositis Vestibulum

Jiangyin Dongli New Materials Technology Co., Ltd. specializes in the comprehensive development and manufacturing of high-performance fiber composite materials, focusing on sectors like aerospace engineering and automotive manufacturing. Our 32,000-square-meter complex incorporates precision-controlled production environments, including 100,000-grade purification zones, ensuring the highest quality in every **carbon aramid fabric** we produce. As a one-stop factory with full process control, we integrate R&D, weaving, and various composite manufacturing processes (Autoclave, RTM, etc.). Praevidemus maturam materiam innovationis et peritia machinalis ad auxilium clientium ad definitam consequendam Optimal carbonis ad rationem aramidis pro compositis hybrid pro earum applicatione requiritur, utrum prioritas sit altae rigoris an superior ictum detrimentum tolerantiae. Adhaesimus severitatis qualitati signa ad fidem faciendam Vires interlaminares tondendas laminas carbonis aramidis fabricae global obvium industriam postulat.

Frequenter Interrogata (FAQ)

1. Quae est prima utilitas per a ipsum aramid fabricae hybrid in pura fibra ipsum?

Primaria utilitas est damnum tolerantiae impulsum. The aramid fibers absorb kinetic energy through localized deformation, preventing catastrophic failure and crack propagation that are common in brittle, pure carbon structures.

2. Quomodo fabrum determinet? Optimal carbonis ad rationem aramidis pro compositis hybrid ?

Proportio determinatur applicationis specificis requisitis. Si rigor est summo prioritate, ratio carbonis dives (v.g. 75:25) adhibetur. Si praesidium impulsum criticum est, ratio aequior (v.g., 50:50) eligitur ad effusio energiae augendam.

3. Quid sit? Modulus librans et impactus resistentiae in fabricae carbonii aramidis ?

It refers to the trade-off in composite design: increasing the carbon content boosts the elastic modulus (stiffness), but decreases impact resistance. Engineers must find the blend that satisfies minimum structural stiffness requirements while maximizing resistance to unexpected physical damage.

4. Quid est? Vires interlaminares tondendas laminas carbonis aramidis fabricae tanti momenti?

Tondendas vires interlaminares (ILSS) crucialis est quia vinculum qualitatem inter stratis fabricae metitur. Low ILSS means the layers can easily separate (delaminate) under out-of-plane forces, leading to structural failure even if the fibers themselves are strong.

5. Quod probat sunt pro Impact spissitudo analysis of carbonis aramidis hybrid fabricae ?

Impact toughness is typically analyzed using standardized tests like Charpy or Izod impact testing, which measure the total energy absorbed by the material until failure, providing a quantitative measure of the material's damage tolerance.